Biomass pellet Machine

3200000.00 INR/Unit

Product Details:

- Country Of Origin India

- Motor Power 215 Horsepower (HP)

- Frequency 1 Hertz (HZ)

- Model No JKEP01

- Click to View more

X

Biomass pellet Machine Price And Quantity

- 3200000.00 INR/Unit

- 1 Unit

Biomass pellet Machine Product Specifications

- 160 Watt (w)

- India

- 1

- 215 Horsepower (HP)

- 1 Hertz (HZ)

- JKEP01

- MS

- Automatic

- PLC Control

- Biomass Pellet machine

- 3x1.6 Meter (m)

- 2 Ton

- 1 Newton

- Pellet

- Electric

- 160 Watt (W)

- Withe

- 2000 Kilograms (kg)

- NA

- 1500 RPM

- 215 Horsepower (HP)

- 2 Ton

- Yes

Biomass pellet Machine Trade Information

- Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Western Union

- 1 Unit Per Month

- 30 Hours

- No

- Asia

- All India

Product Description

- Small-Scale (Home/Cottage Industry) Pellet Machines:

- These are compact, often portable, and ideal for producing limited quantities of pellets (50-500 kg/hr capacity).

- They typically use aflat diemechanism, known for its simple structure, lower cost, and ease of operation and maintenance.

- Examples include the 7.5 HP Biomass Pellet Machine from A.P. International, with a capacity of 500 kg/hr, available for around 75,000.

- How They WorkThe process of making pellets involves several steps to transform loose biomass into a standardized fuel:

- Raw Material Preparation: Biomass waste is collected, cleaned of impurities, and ground into fine, uniform particles using a hammer mill or chipper.

- Moisture Control: The material is dried to achieve an optimal moisture content (typically between 8-15%) for effective pellet formation.

- Pelletizing (Extrusion): The prepared biomass is fed into the machine, where rollers apply immense pressure to force it through small holes in a metal die. The intense friction activates the natural binding agent (lignin) in the biomass, which fuses the particles together.

- Cutting and Cooling: A rotating knife cuts the extruded material into desired lengths, and the hot pellets are then cooled in a counter-flow system to harden their shape and reduce moisture content further.

- Packaging: The finished pellets are screened to remove any fine particles and then packaged for storage or transport.

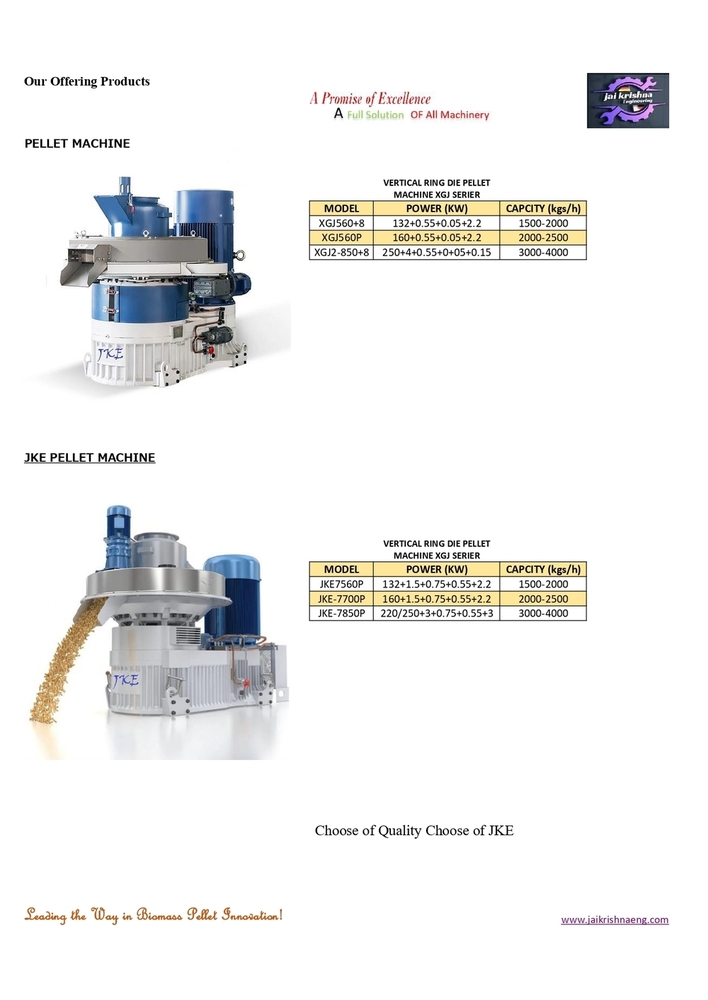

Notable ProductsHere are a few specific products available in the market:- Yulong XGJ560 Centrifugal Biomass Pellet Making Machine

- Capacity:2000 Kg/hr.

- Features:An automatic, electric-powered machine with a robust design for industrial use, known for its efficient production.

- Biomass Flat Die Pellet Plant and Machines

- Features:A versatile and efficient solution offered by FABON for converting various biomass wastes into quality pellets. These are typically lower cost than ring die systems.

- Farmiaze Engitech 7.5 HP Biomass Pellet Machine

- Capacity:Up to 500 kg/hr.

- Features:A semi-automatic, user-friendly option ideal for small-to-medium scale operations.

A biomass pellet machinecompresses raw organic waste materials like sawdust, wood chips, and agricultural residues into dense, uniform, and energy-efficient fuel pellets.

Types of Biomass Pellet Machines

Biomass pellet machines are categorized mainly by their production capacity and die type (flat die or ring die), catering to various needs from small-scale home use to large industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email